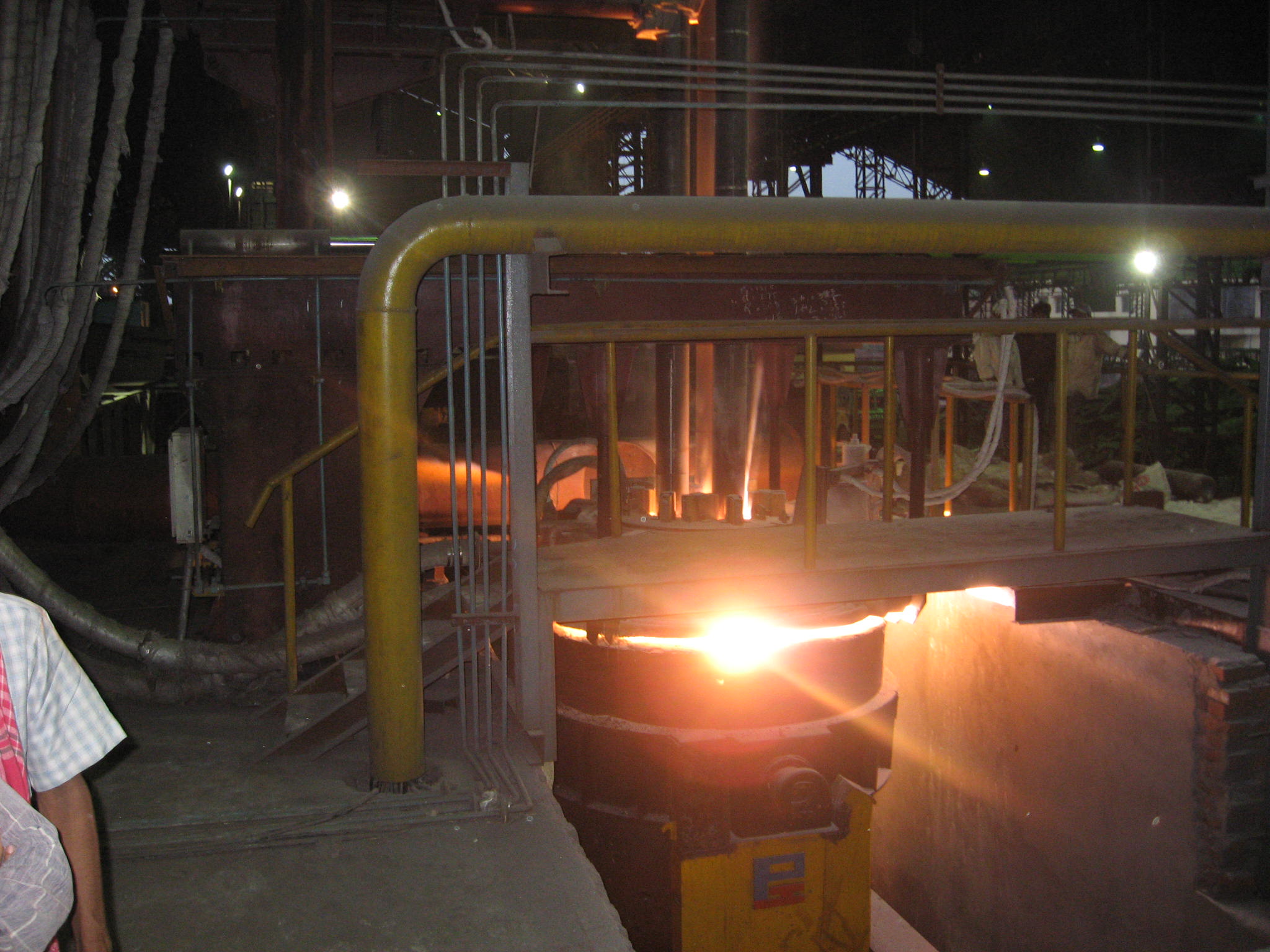

LADLE REFINING FURNACE

Ladle refining furnaces are used to improve the chemical composition and homogeneity of steel products and increase productivity in steel-making operations. By allowing the steel-making furnaces to be used exclusively as melting units, tap-to-tap times are decreased, increasing the production capacity and decreasing overhead costs per ton of steel produced. It also helps in flexible scheduling as liquid metal can be held at the proper temperature while waiting for caster availability.

The objectives of ladle metallurgy are the following.

- Homogenization – Homogenization of chemical composition and temperature of liquid steel in the ladle.

- Deoxidization or killing – Removal of oxygen.

- Superheat adjustment – Heating of the liquid steel to a temperature suitable for continuous casting.

- Ferro alloys and carbon additions – Making adjustments in the chemistry of liquid steel.

- Decarburization – Removal of carbon for meeting the requirement of certain grades of steel.

- Desulfurization – Reduction of sulfur concentrations.

- Dephosphorization – Reduction of phosphorous concentrations.

- Micro cleanliness – Removal of undesirable nonmetallic elements.

- Inclusion morphology – Changing the composition of remaining impurities to improve the microstructure of the steel.

- Mechanical properties – Improvement in toughness, ductility, and transverse properties.

- Reduction of refractory consumption.

- Reduction in total cost.

Megatherm LRF Capacity:

12 Ton LRF to 100 Tons LRF

Advantages of Megatherm LRF:

- 30-year-old industry-leading design and engineering team

- Lowest operating cost

- Minimal spares requirement and cheap after-sales spare parts

- Exhaustive PLC-based diagnostics, auto alarms and preventive maintenance

- Remote access for remote troubleshooting and servicing

- Conductive electrode arm

- Tilt-able hood

- Mechanized slag raking system

Special Feature: Conductive Electrode Arm

Current conducting electrode arms are a melt-shop-proven design that provides efficient cooling as well as reduced electrical loss. The utilization of copper-clad (copper and steel) arms combines the high strength of steel while exhibiting the high conductivity and current-carrying ability of copper.

Due to their outstanding design and optimal materials, Megatherm electrode arms deliver lower electric operating costs, low graphite consumption, higher process speed, easy handling, optimal symmetry, and maximum efficiency.

Advantages of Conductive Electrode Arms

- Low operating costs

- Minimal shutdown times

- Easy handling

- Optimum symmetry

- Highest electrical efficiency