REMOTE SERVICE – MEGALINK

Category:

Automation

Imagine

- Not having to wait hours for service engineer to arrive for breakdowns

- Having issues handled by senior most technical experts within minutes

- Being able to diagnose problems remotely

- Being able to tune panel and change equipment settings remotely

- Reducing down time by 50% to 60%

Remote Access

- Ethernet / Wifi connectivity to be provided in Panel room

- Megatherm remote access devices will be installed

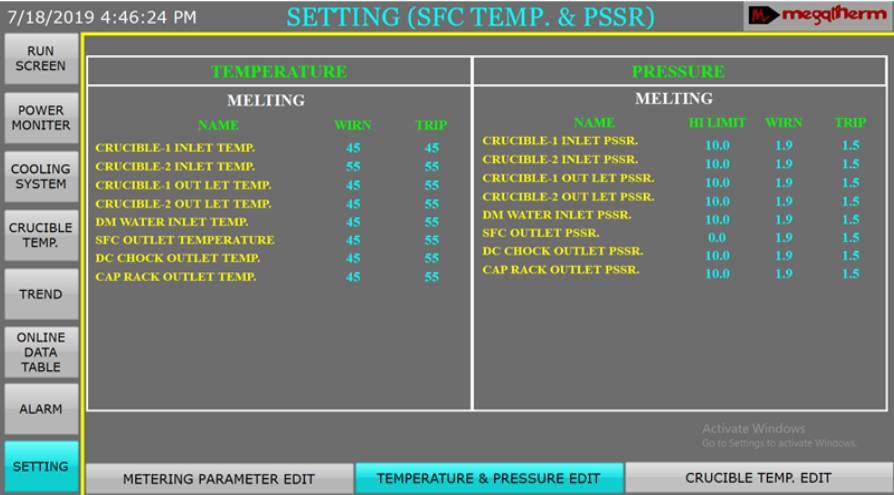

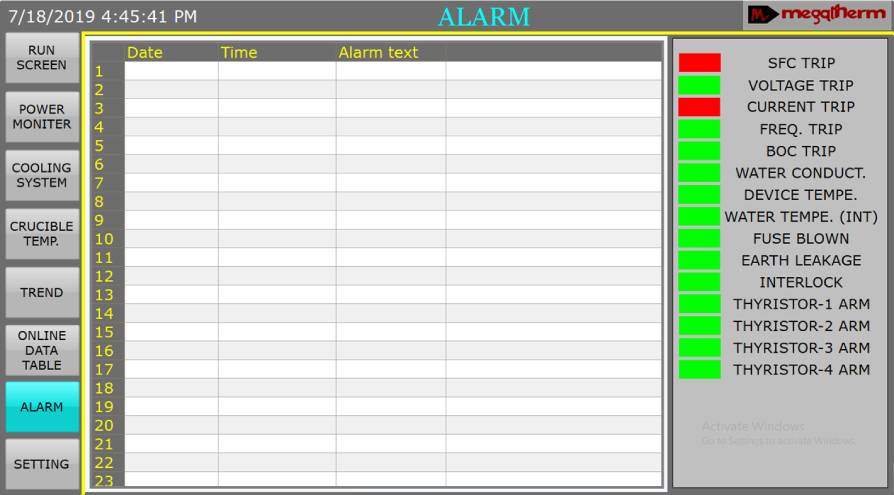

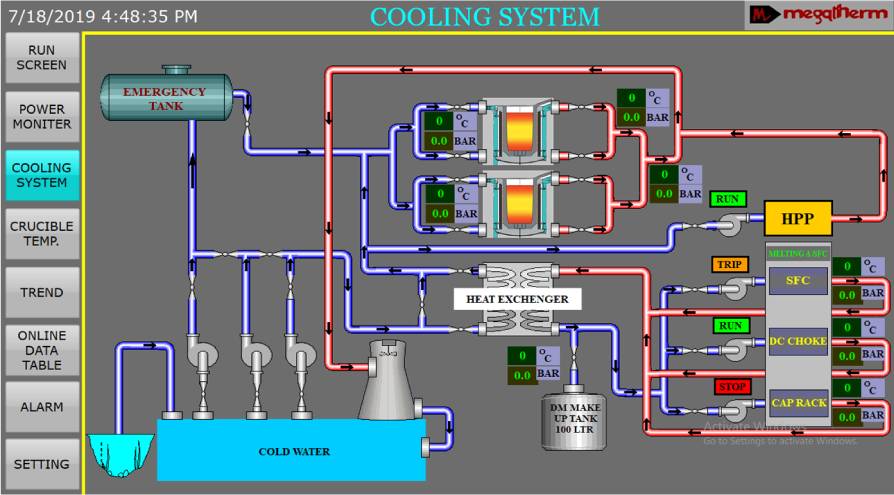

- Megatherm engineers as well as plant head will have access to PLC live feed

- Diagnostics can be done remotely

- Changing panel parameters will also be possible remotely

Remote Servicing

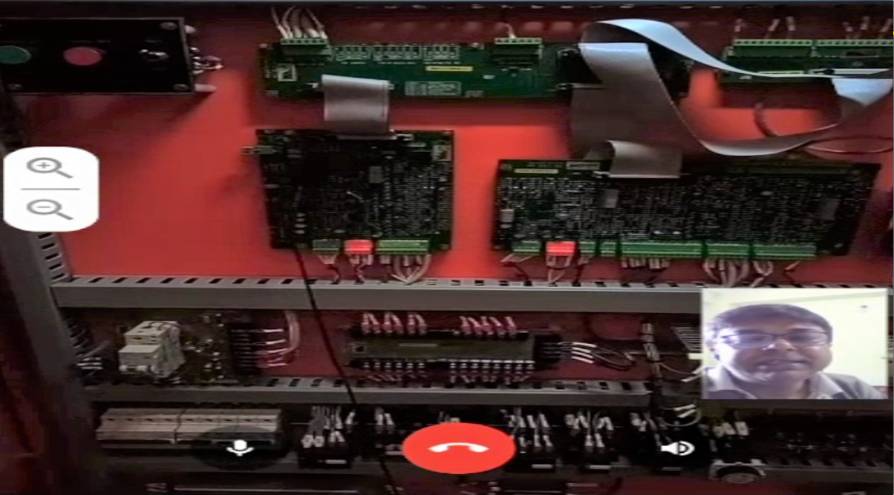

- MegaLink App will be installed in tab of trained plant engineer

- During breakdown ticket can be raised and video call will be arranged

- Remote servicing can start immediately without waiting for service engineer

- As much as 80% of breakdowns can be resolved remotely leading to 50% to 60% reduction in down time

Other advantages:

- Call recording for future reference, training and analysis

- Files can be shared during call

- Instructions/Text can be shared during call

- Remote erection / site mapping also possible

- Drawings can be opened during call