PLANT LOAD MANAGEMENT

Category:

Automation

PLC Based Load Manager

Brief Description of the Load Manager:-

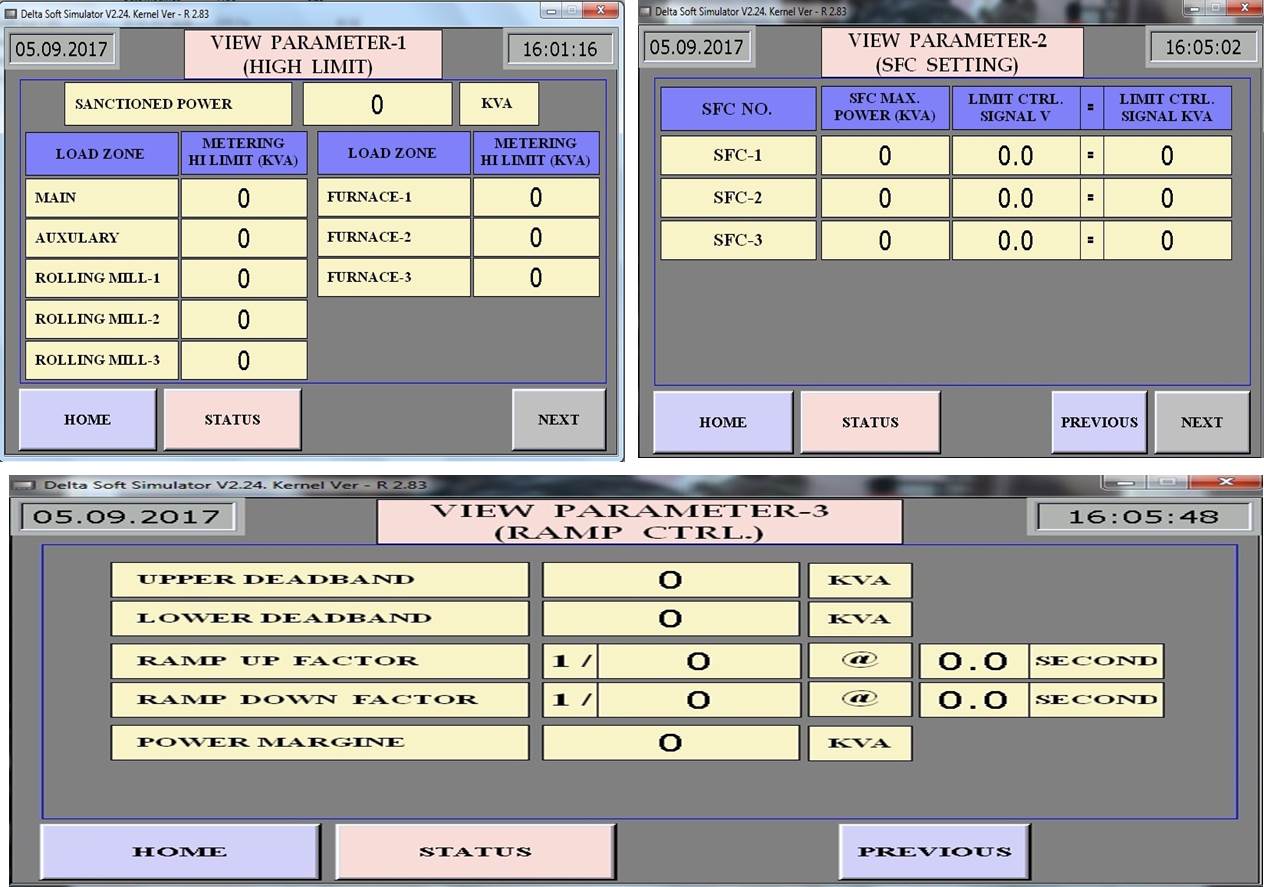

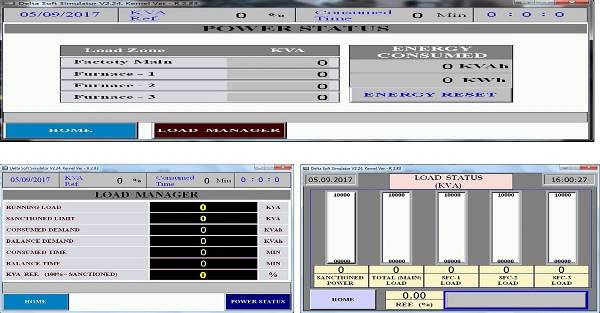

- The system is used for optimum utilisation of sanction demand. The operator will need to provide the sanctioned demand value and then the system will monitor the consumed power continuously. In no case it will allow the demand to cross the demand limit. The equipment has the facility to synchronise the demand Cycle Time in 30 Min or 15 Min slots with the main commercial meter. The system will also monitor the achievable demand by calculating the power consumed during elapsed time and the time left for that demand cycle time. If the system finds that the achievable demand is less than the sanctioned demand then the system will increase the current limit signal level to push higher power to the furnace to utilise the sanctioned demand and vice-versa.

- The Sanction power in terms of KVA / KW has to be fed manualyl in the Touch Screen. Furnace will be made to run in such a way that the demand will not cross the Sanction Power in a particular Demand Cycle Time.

- There is provision for priority selection of furnaces. Those furnaces which are higher in priority will run in full load and balance furnaces will take the load in such a way that total demand will not exceed sanctioned demand

Instantaneous Demand Controller

This system is designed for optimum utilisation of Generation Power or Purchased Power. The system will need input ofthe allocated power in terms of KVA or KW. Allocated power can interface directly with the PLC in 4-20 mA Signal format or operator will need to input in the touch screen. The system will continuously monitor the instantaneous power. The System will run in such a way that the total load will always be maintained within the allocated power.

- Features of the Demand Controller

- Master PLC Control Panel Mainly consists of PLC, Touch Screen (HMI)& Multifunction meter.

- Individual Salve Control Box along with Multifunction meter for the Furnace.

- Power Sharing in between all the furnaces

- Interface between Multifunction meter and PLC

- Priority selection of furnaces

- Optimum Utilisation of the Sanctioned Demand or Power Generation

- Restrict the Furnace Power to Run the Other equipment / Machine of the Plant such as Rolling Mill, CCM & Other Auxiliary System.

- Real Time data monitoring.

- Monitoring Total Load and Energy consumption of the Plant.