INDUCTION MELTING FURNACE

Category:

Steel Melt Shop Equipment

Green Furnace

The Green Furnace: Our popular low-frequency model has been further improved upon leading to furnace orders of 19MTPA capacity out of which 6 MTPA are orders of plants using furnaces of other makes. Some of the largest secondary steel manufacturers globally are joining the Green revolution. Below are the reasons why…

- Green furnace incorporates the best aspects of parallel as well as series circuits to give the lowest energy consumption and higher productivity

- Latest SMD-based inverter with a digital interface

- Fibre optics used in inverters & signal boosting in rectifiers

- Guaranteed energy consumption of 465 kWh/t using mill heavy/end cutting scrap

- Guaranteed 30 kWh/t – 40 kWh/t lower than all other latest furnaces and 60 kWh/t – 75 kWh/t lower than previous generation furnaces

- 9% – 11% higher productivity compared to other brands

- Power factor of 98%

- No capacitor switching. Sustained power throughout the heat cycle

- High power pickup achieved via voltage boosting

- Eight energy consumption and productivity improvement features

- Harmonic distortion is restricted strictly within IEEE 519 norms

- State-of-the-art digital system with alarms, remote access, digital parameter displays, data logging, trend analysis, etc.

Topology Comparison

| Series Circuit | Parallel Circuit | Green Furnace | |

| Name | Voltage Source Inverter | Current Source Inverter | Voltage-Boosted Current Source Inverter |

| Power Pickup & melt rate | Good power pickup and high melt rate | Poor power pickup. Low melt rate | High power pickup and best melt rate due to voltage boosting and low-power consumption |

| Power Factor | 96% – 97% (from start) | Max 93% – 94% (from 80% of rated power) | 97% – 98% (from 40% of rated power using CPF system) |

| Capacitor Switching & frequency | Switching is not required. Low frequency maintained throughout the heat cycle | Switching Required. Done via PLC-controlled pneumatics. Medium freq due to the large frequency range | Switching is not required. Low frequency maintained throughout |

| Energy Consumption | Higher than Green | Higher than Green | Lowest due to 8 Green furnace features |

| After-sales parts cost | Expensive due to high current carrying devices | Cheaper than a series circuit | Cheaper than a series circuit |

| Reliability (Shock load and short circuit resilience) | Poor due to the presence of a DC link discharge capacitor | Better due to the presence of heavy current sourcing DC reactor | Better due to the presence of heavy current sourcing DC reactor |

Features of Green Furnace & Impact on Performance:

| Feature No. | Feature | kWh/t Saving | Productivity Improvement |

| 1 | Compact Layout & improved copper sections lead to minimal current density and line losses | 3 – 5 | 1% |

| 2 | Nano Cable Design: Lowest cable loss & voltage drop | 8 – 12 | 1% |

| 3 | Power factor of 98% as seen in a series circuit | 2 – 3 | 2% |

| 4 | Strict Harmonics Control | 2 | 0% – 1% |

| 5 | Low Loss Higher Rated Capacitors | 2 – 3 | 0% – 1% |

| 6 | Automatic Voltage Boosting, High Power Pickup, Higher Voltage (4150V up to 8MW/5250V 10MW onwards) | 8 – 10 | 2% |

| 7 | Higher power pickup. Highest Load Factor. Stretching Increased. | 10 | 1% |

| 8 | Tight Frequency Range (up to 280 Hz unlike others which go up to 400+ Hz) because of no capacitor switching | 25 – 30 | 2% |

| Total | 60 – 75 | 10% |

End Result

- 60 – 75 kWh/t savings compared to previous generation furnace

- 25– 30kWh/t lower than the latest model of all other makes

- 9% to 11% higher production than any furnace in the market

Feature 6 and 7 explained:

Load Graph 18th Heat 14.5 MW with Voltage Stretching

LOAD FACTOR-95%

Load Graph without Voltage Boosting

LOAD FACTOR– <90%

Feature No. 2: Nano Cable Design

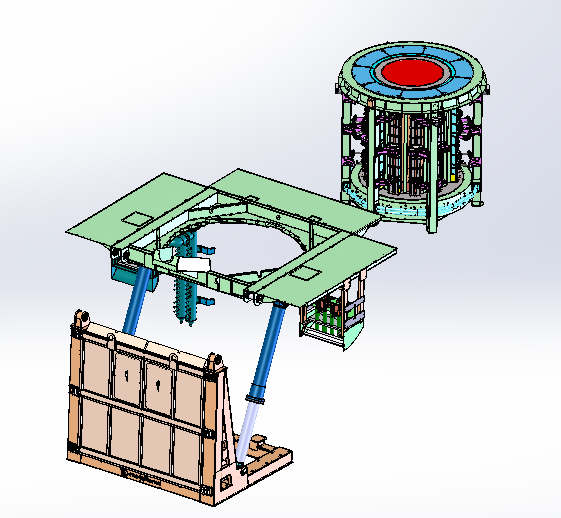

Typical Layout