IMF AUTOMATION

Digital Module – Generation-1

HARDWARE:

- PLC- Make SIEMENS

- 10 inch touch screen HMI on panel

- Wiring & cabling upto 50m

- I/O Modules

KEY HIGHLIGHTS:

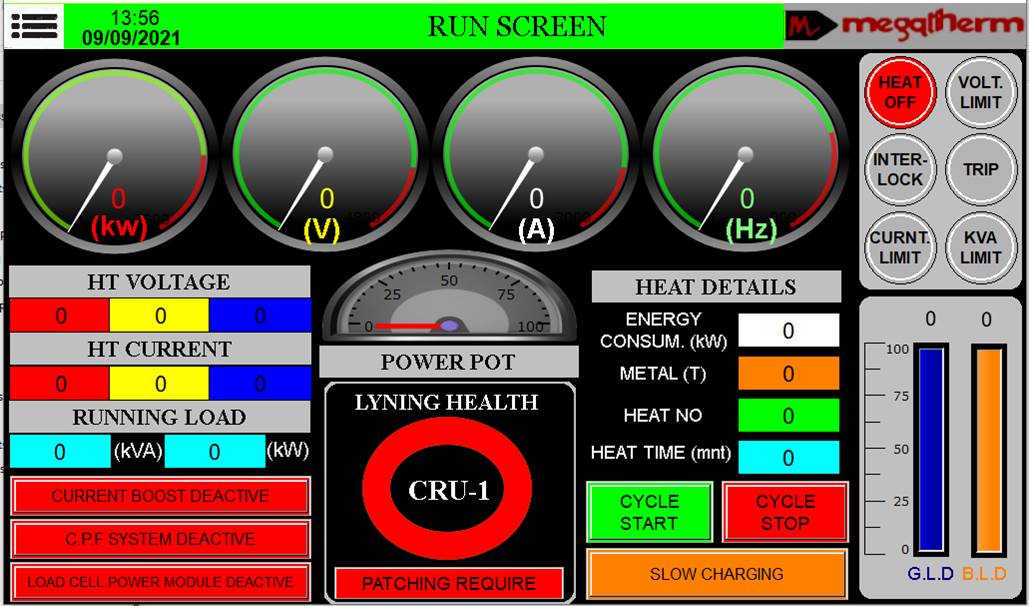

- SFC Parameters: Digital display of all panel parameters with higher accuracy compared to analog meters

- Interlocks: All interlocks displayed digitally

- Data Logging: Data logging in the pen drive

- Trends Analysis: Furnace parameter trends can be viewed for post-production analysis and operations improvement

Digital Module – Generation-2

| HARDWARE & SOFTWARE: | HARDWARE FOR SAFETY PACKAGE: |

|

|

Digital Module – Generation-2

| Packages | Features |

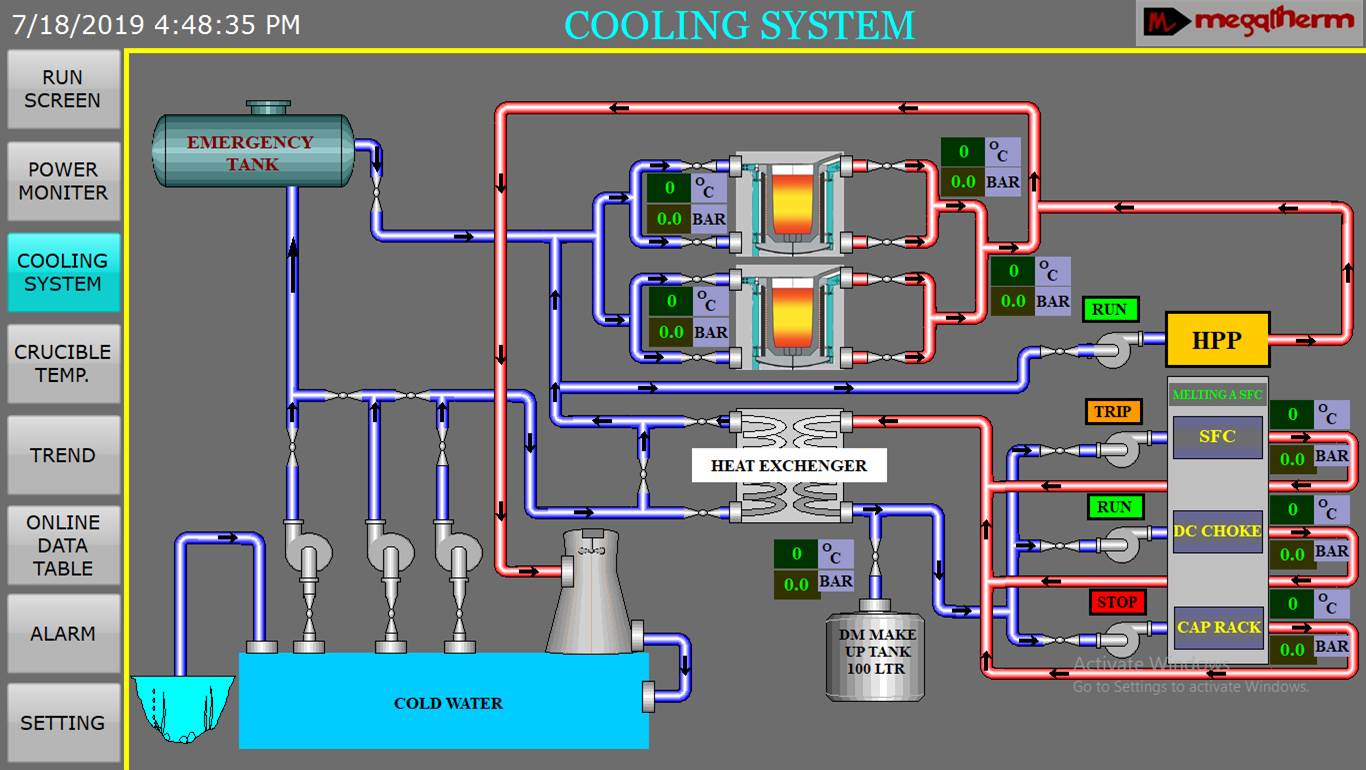

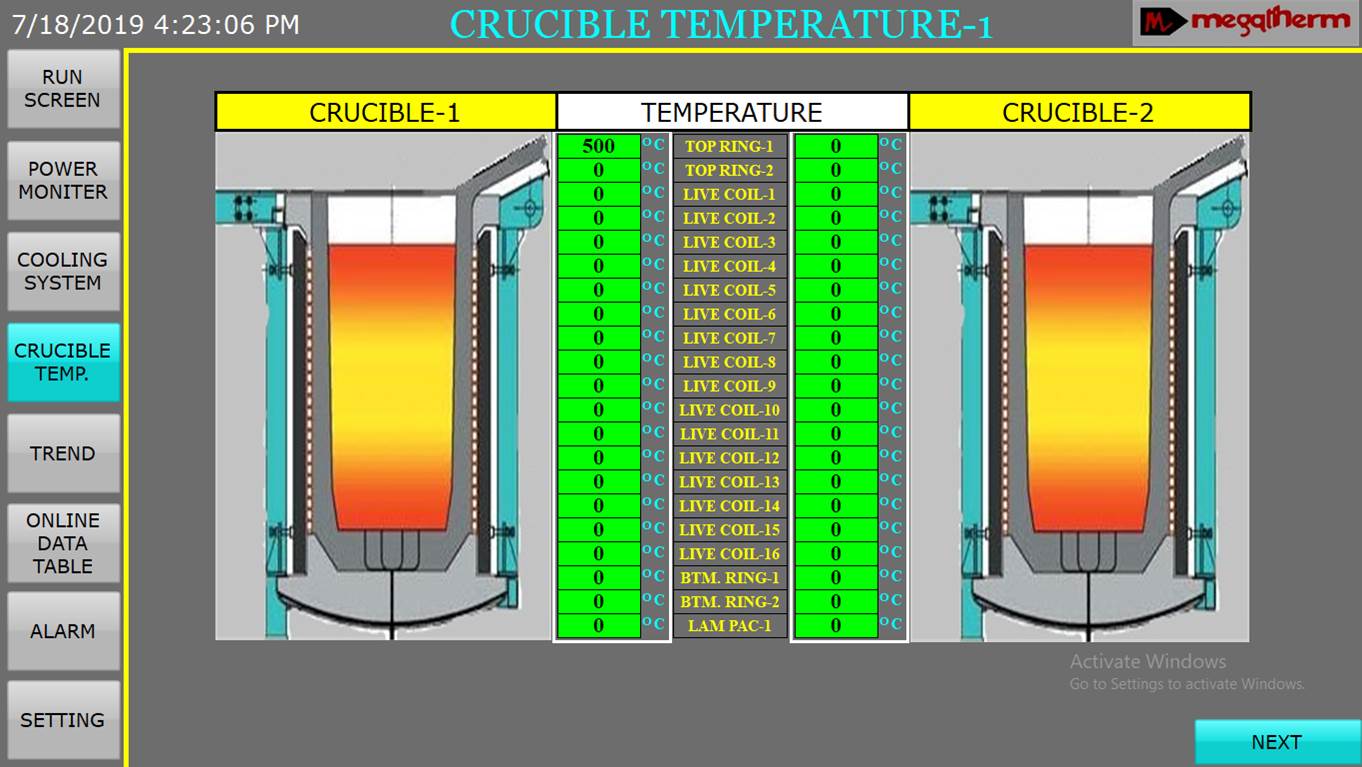

| Diagnostics Package | Continuous temperature and pressure sensing at critical points for pre and post-incident diagnostics |

| Operations Package | Energy Counter, Slow Charging Alarm, Melt Analyzer, Auto Heat Off |

| Maintenance Package | Water level, Water Conductivity, Automatic Maintenance Alarms |

| Systems | Features |

| Accident Prevention System | Digital GLD, Lining Health Detector, Bottom Earth Leakage Sensor |

| Remote Access | Virtual Scada is accessible via any device from anywhere |

| Megalink | Remote servicing of furnace |

-

KEY HIGHLIGHTS (ALL SYSTEMS & PACKAGES)

- SFC Parameters –Digital display as well digital setting of parameters. No need to touch cards.

- Remote Access (virtual SCADA) –All parameters can be viewed and set remotely. Hence, remote diagnosis is possible. Virtual SCADA enables access to all the data & diagnostics on any device.

- Energy Counter –kWh limit for the heat can be set and the counter ticks down. Power can be reduced once limit has been exhausted.

- Reports –Power, voltage & pressure trends and graph for post-production analysis,

- Melt analyser- Daily reporting of no. of heats, total energy consumed, productive time, low power time, down time & slow charging incidents.

- Auto Diagnostics & Preventive maintenance – All interlocks displayed digitally. Temperature warning of DM Inlet, SFC outlet, chokes outlet, Capacitor rack outlet and crucible inlet/ outlet.Pressure warning of DM water, raw water & Hydraulic oil (HPP). Water level & water quality measurement. Automatic maintenance alarms.

- Slow Charging Alarm –Whenever charging is slow the system will give warning and the incident will be logged and displayed in reports for post-production analysis.

- Auto Heat Off –After every heat the furnace can automatically turn off to prevent residual energy wastage.

- Accident Prevention Module –Refer to description pages.

- Mega link –Refer to description pages

Accident Prevention Module

Hardware & Software:

- Siemens LOGO PLC

- Delta make HMI

- Lining health detection devices

- Bottom earth leakage detection devices (for On-BELD)

- Accident Prevention Panel with relevant cards, feedback & wiring

- 2 Nos. crucible earthing contactor box

- Pneumatic cut-off switch

- Pneumatic Cylinder

- Solenoid Valve (FRL Unit)

- Pressure Gauge (FRL Unit)

- Air Filter (FRL Unit)

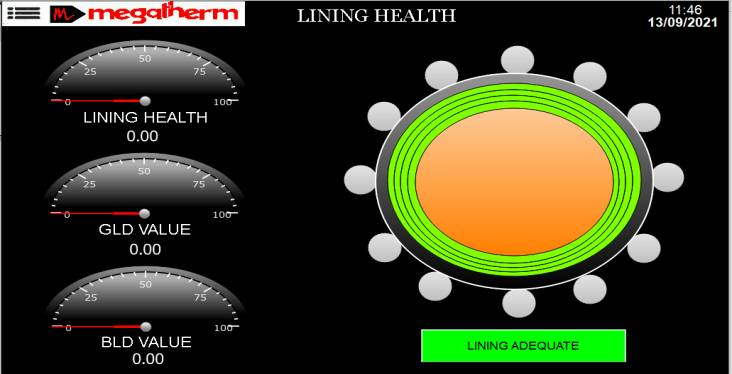

Lining Health Detection

Concept:

Many times when an induction furnace is partially or completely full of liquid metal and there is power disruption, breakdown or GLD tripping there may be risk of metal leakage.

The team at the site is unaware of the status of the earth leakage as the furnace is in the power-off condition. In addition, the standard earth leakage system is for an entire circuit which may give rise to some leakage current that may not be related to metal leakage and may cause nuisance tripping. This causes confusion and creates risk when the furnace has to be restarted.

To address this, Megatherm has launched Lining Health Detection System. This system indicates earth leakage/lining health data specific to the crucible when the furnace is in off condition or test mode. Now, in case of any breakdown or tripping the site team will know whether it is safe to restart the furnace. This system activates automatically and PLC records data of entire patching cycles to create a database for future reference

Lining Health Detection

Advantages:

- Earth leakage/lining health data available even if the furnace is in the off condition/test mode

- Crucible-specific data available eliminating circuit leakage current and other nuisances

- Auto Activation of the system when the furnace is off / prior to pouring of metal

- Capturing data of entire heat cycles to create a database for future reference

- Works in unison with the existing GLD system

- Improves plant safety and prevents accidents

- Gives clarity and confidence to the site team and melters to operate the furnace or tap out liquid metal after breakdown/tripping

On-BELD

Concept:

ONB-ELD or Online Bottom Earth Leakage Detection system works along with the standard GLD system while the furnace is “Online”

It gives a percentage reading of bottom earth leakage only

It is not affected by leakage current in the tank circuit

Bottom earth leakage reading is displayed in HMI along with standard GLD reading and together with Lining Health Detection it forms a robust accident prevention system